Jlevi SW | Full Factory Tour of aFe - See How It's Made w/ Photos

#1

Contributors

Thread Starter

Join Date: Apr 2006

Location: Santa Clara, CA

Posts: 134

Likes: 0

Received 0 Likes

on

0 Posts

Hey there guys!

Last week, Nick and I had the pleasure and privilege of touring Advanced Flow Engineering, also known as aFe. We knew that aFe is a leader in our industry, with quality products and fantastic designs - but we had no idea what a polished and impressive operation they were running. It is our pleasure to share with you some photos and videos of the aFe factories.

Starting off, we knew we were in the right place when we saw this aFe truck. Actually, we were at their old facility, which now only manufactures exhausts. We had to cross the street to get to the real factory:

Yep - this was the place!

Sorry, we skipped taking pics of the main room, because we were too busy signing agreements (not to share information that is proprietary - we've had to obtain permission for each of these photos!). It was really nice - we should have taken pictures, but our initial reaction was "hrm, maybe we should put the camera away" till our sales rep arrived.

Little area showing what kind of stuff dealers can display...

3D Model Makers - very useful... They churn out rapid prototypes so they can test immediately:

Last week, Nick and I had the pleasure and privilege of touring Advanced Flow Engineering, also known as aFe. We knew that aFe is a leader in our industry, with quality products and fantastic designs - but we had no idea what a polished and impressive operation they were running. It is our pleasure to share with you some photos and videos of the aFe factories.

Starting off, we knew we were in the right place when we saw this aFe truck. Actually, we were at their old facility, which now only manufactures exhausts. We had to cross the street to get to the real factory:

Yep - this was the place!

Sorry, we skipped taking pics of the main room, because we were too busy signing agreements (not to share information that is proprietary - we've had to obtain permission for each of these photos!). It was really nice - we should have taken pictures, but our initial reaction was "hrm, maybe we should put the camera away" till our sales rep arrived.

Little area showing what kind of stuff dealers can display...

3D Model Makers - very useful... They churn out rapid prototypes so they can test immediately:

#2

Contributors

Thread Starter

Join Date: Apr 2006

Location: Santa Clara, CA

Posts: 134

Likes: 0

Received 0 Likes

on

0 Posts

One of the things that sets aFe apart is that the parts are all bolt-on with no external brackets... all integrated, built on to the INSIDE of the part, so that they can make the manifolds as large as possible for free-flow!

A solidworks CAD drawing, and some "combs" that we will show you later... they're cool.

What's this? Porsche OEM intake box? Nice. Can't wait to sell this on our other division.

Bins of goodies.

Now THIS thing is cool. This is how they test the filtration. Unlike many companies, when aFe tells you "99.8% filtration" - they've actually measured it, using this custom built machine.

They take this test dust, which has a specific weight:

A solidworks CAD drawing, and some "combs" that we will show you later... they're cool.

What's this? Porsche OEM intake box? Nice. Can't wait to sell this on our other division.

Bins of goodies.

Now THIS thing is cool. This is how they test the filtration. Unlike many companies, when aFe tells you "99.8% filtration" - they've actually measured it, using this custom built machine.

They take this test dust, which has a specific weight:

#3

Contributors

Thread Starter

Join Date: Apr 2006

Location: Santa Clara, CA

Posts: 134

Likes: 0

Received 0 Likes

on

0 Posts

Then, they run the machine with a filter bolted on, and they then weigh the amount of dust that is left. Anything that is gone has been trapped by the filter. They can thus calculate exactly what percentage of the debris is filtered out.

Quick view out on part of the facility

Now, here is another custom built machine that measures flow dynamics. This machine enables them to know what the increased air flow of a filter will be when compared with stock. So, when we tell you "70% increase" - we're not just guessing!

This is a filter for a motor home... it's half the size of Nick. Which isn't saying that much - but still.

An aFe intercooler. aFe is one of the only manufacturers that puts veins in their intercoolers to distribute air (and thus heat) evenly, for maximum cooling capacity

A little bit of inventory for the smaller stuff.

What's this? TRD boxes?

Yes, that's right. aFe is the OEM supplier to Toyota for all TRD filters.

Impressed yet?

Quick view out on part of the facility

Now, here is another custom built machine that measures flow dynamics. This machine enables them to know what the increased air flow of a filter will be when compared with stock. So, when we tell you "70% increase" - we're not just guessing!

This is a filter for a motor home... it's half the size of Nick. Which isn't saying that much - but still.

An aFe intercooler. aFe is one of the only manufacturers that puts veins in their intercoolers to distribute air (and thus heat) evenly, for maximum cooling capacity

A little bit of inventory for the smaller stuff.

What's this? TRD boxes?

Yes, that's right. aFe is the OEM supplier to Toyota for all TRD filters.

Impressed yet?

#4

Contributors

Thread Starter

Join Date: Apr 2006

Location: Santa Clara, CA

Posts: 134

Likes: 0

Received 0 Likes

on

0 Posts

Wow... big warehouse.

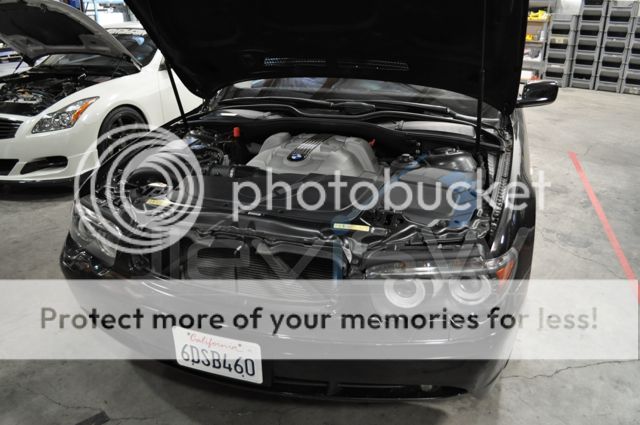

Here is a little project... very exciting for you E65 owners.

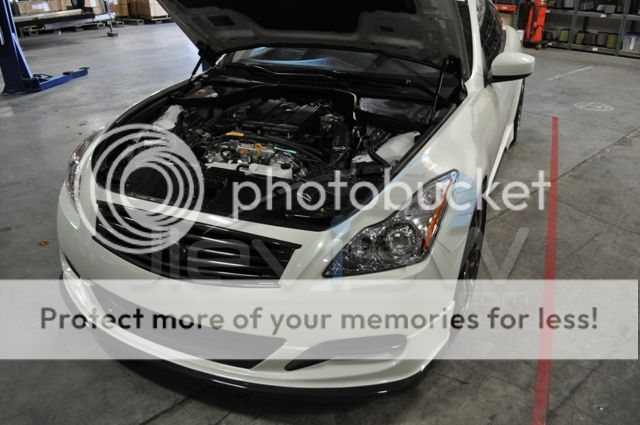

Some JDM lovin, too.

Seems like there are miles and miles of bins, towering above you. This is just a litttle bit bigger than our warehouse

Now to the good stuff.... manufacturing!

Here are a bunch of filtration elements already pressed. How did they get made? Keep reading, we'll get there.

This is how they are bound together, with the metal strips.

Metal strips are made right here, 10 feet from where they will be used for filters.

Dare you to stick your finger in there.

Tons of bottles that will be filled up and sent to people for recharge/cleaning kits...

#6

Contributors

Thread Starter

Join Date: Apr 2006

Location: Santa Clara, CA

Posts: 134

Likes: 0

Received 0 Likes

on

0 Posts

Vats of the chemicals used for the above kits.

Just some stuff that's already packed up on a pallet.

Remember those combs? This is what they're used for. They keep the pleats evenly spaced while the polyurethane dries.

This is a heated table. The whole thing is hot, to make the polyurethane dry slowly and properly. You'll notice that there are little nubs in the mold. They keep the filter element even and in place while the drying happens.

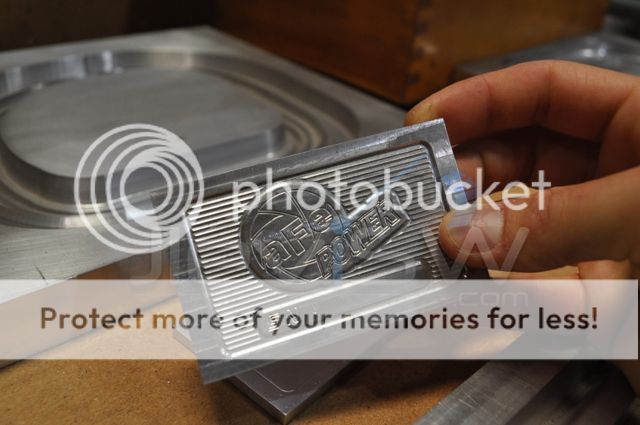

This is a mold for another filter. That's how the logo goes in. They make these molds in-house. More on that later.

4-sided mold, 3 sides already done.

#7

Contributors

Thread Starter

Join Date: Apr 2006

Location: Santa Clara, CA

Posts: 134

Likes: 0

Received 0 Likes

on

0 Posts

Now THIS is LEGIT. A machine does all of this. I'll let the video explain:

WATCH THIS VIDEO!

Pleating machine in action... now, on to the less amazing stuff, but still very impressive!

Lots of inventory

M5 intake being held in captivity. Buy this little guy today so we can find him a good home!

Bins of parts

#8

Contributors

Thread Starter

Join Date: Apr 2006

Location: Santa Clara, CA

Posts: 134

Likes: 0

Received 0 Likes

on

0 Posts

Stuff waiting to be packed into kits

An assembly line where workers put things in boxes. Everything has a part number - even the boxes. Even the instruction manuals. Even the baggies that hold the screws. That's how you avoid making mistakes! Henry Ford would be so proud, he probably would pick up an intake system (Ford F150 systems are one of their bestsellers).

Bestsellers are kept closest to the shipping area, obviously. There are no BMW or Porsche parts there... yet. aFe has only been doing European cars for a couple of years.

Did you know that Takeda, an up-and-coming intake manufacturer for JDM cars, is owned by aFe?

Hey, this looks familiar! This is OUR bestseller, and their bestselling BMW model... for the N54!

#9

Contributors

Thread Starter

Join Date: Apr 2006

Location: Santa Clara, CA

Posts: 134

Likes: 0

Received 0 Likes

on

0 Posts

WHAT'S THIS IN THE R&D DEPARTMENT OF THE EXHAUST SHOP? Yep... a 335... expect to see some GOOD stuff pretty soon!

Prototype being made for something.... hrmm....

All aFe exhausts use OEM-like hangars for ease of installation

The exhaust shop is very big, too. aFe's whole operation used to run out of this shop, but now their new facility is 3-4x the size - and they use this one just for exhausts and CNC machining.

In-House Dyno. You know all the times we say that "this part gains 12HP" - We weren't bluffing. aFe does NUMEROUS runs, chooses the lowest number, and then uses that as their advertised gain. In reality, most of the parts make more power, but they, like any respected manufacturer, like to underpromise and over-deliver.

To those of you who think some of these parts may not make any power - or may even lose power... Not a chance. aFe tests in a multitude of conditions, allowing the cars the proper 50-100miles of driving time before re-dynoing in similar conditions. These parts are guaranteed to make power and increase efficiency.

#10

Contributors

Thread Starter

Join Date: Apr 2006

Location: Santa Clara, CA

Posts: 134

Likes: 0

Received 0 Likes

on

0 Posts

Because they have TWO in-house CNC machines, they can churn out molds of whatever they want, whenever they want. The result is that there are no corners cut. If it's not 100% perfect, they can walk back and make a new one. No shipping it back to the manufacturer in Asia. How many companies can say that?

More CNC goodies.

CNC molds...

CNC mold of their logo... very cool.

1 of 2 CNC machines. Do you guys know how much these things cost? Yikes.