Evan's E61 Build: Pics, Updates, and Wagon Love for All

#351

Thread Starter

Members

Senior Members

Joined: Feb 2008

Posts: 899

Likes: 13

From: San Diego

My Ride: E61 with all the mods

Model Year: 2008

Engine: N54

MTF flush. The seller of the trans drained most of the fluid prior to shipping so there was only a small amount left, nonetheless I got it out and put nearly the full "dry fill" amount of 1.7qt.

Evan

So easy to get all the fluid out when you can tilt and swing the trans as you need.

Royal Purple was the fluid of choice, it seems to have a proven and positive track record amongst late-model MT BMW owners.

Old MTF in shade

Old MTF back-lit

Evan

So easy to get all the fluid out when you can tilt and swing the trans as you need.

Royal Purple was the fluid of choice, it seems to have a proven and positive track record amongst late-model MT BMW owners.

Old MTF in shade

Old MTF back-lit

#352

Thread Starter

Members

Senior Members

Joined: Feb 2008

Posts: 899

Likes: 13

From: San Diego

My Ride: E61 with all the mods

Model Year: 2008

Engine: N54

I am waiting for the last remaining parts and tools to arrive before diving into my engine rebuild (timing chain tensioner seal and a crank hub counter-hold), I hope to have the rebuild completed next week/weekend!

Evan

Wagon, engine, dog, and transmissions.

Now that the rear end is done, I was able to thuroughly clean and reinstall my M5 brakes.

I am storing some wheels for my buddy (with that ST 6466 E90) garage space is tight so they are stored in my wheel wells! Great looking design! They are from a small company that once was, Forged 1.

Boot and shift knob. These will likely be a temporary solution as I plan to fabricate a gated shifter.

New-to-me oil pan arrived (eBay special) gave it a good cleaning and here is with the others.

I finished cleaning the engine bay, engine wiring harness, and the complete underbody which was either covered in oil from the blown motor of simply dirty from the 105,000 miles of service. EVERYTHING is nice and clean, just the way I like it.

Which brings me to the hurdle I will have to clear for mounting my transmission. My transmission tunnel has a large bulge and unique mounting locations for the 6AT+TC this car previously had and it is radically different than what I need to make the RWD E6X transmission support bolt to the chassis.

This will require a creative solution. I am hoping I can make a hybrid trans support which will utilize my old TC support and those chassis mounts but also reach far enough forward to properly support the MT. The good thing is there isn't a whole lot of weight the support needs to hold, it is more rotational torque from the engine. I will cross this bridge once the engine is in and the trans is mounted but this will arguably be the most "CUSTOM" part of my build...

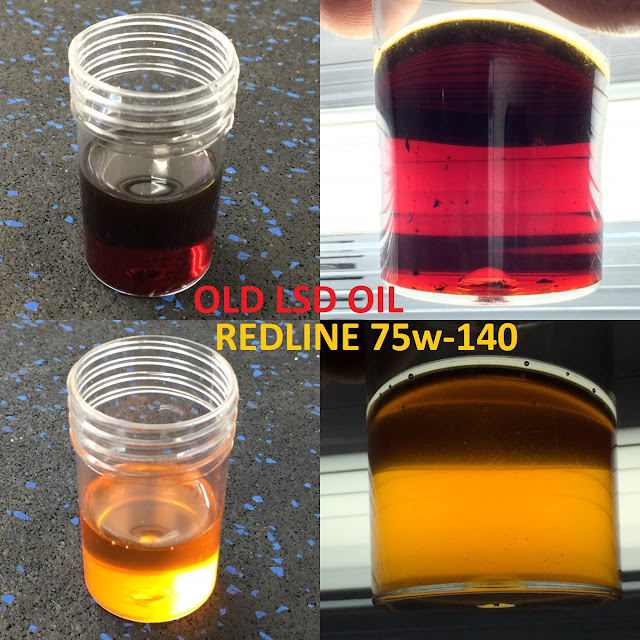

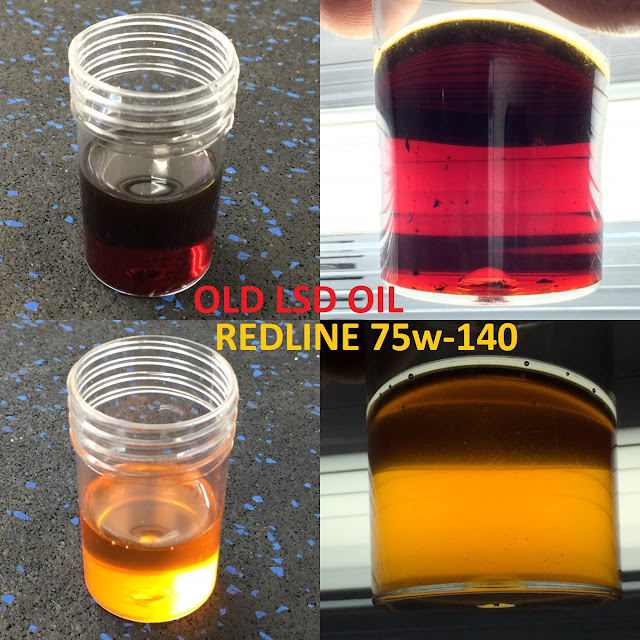

Ordered some Redline 75w-140 (GL-5 +FM) because it sounds like people have had success with it and for the LSD flush it cost only $48, not $200+ for the oem BMW fluid, yes it is $50+ per 500ml.

Easy flush

Although those large particles seem odd, the condition of the old oil seems pretty good, it looks like it had been flushed as least once during it's previous 70,000 mile life.

Evan

Wagon, engine, dog, and transmissions.

Now that the rear end is done, I was able to thuroughly clean and reinstall my M5 brakes.

I am storing some wheels for my buddy (with that ST 6466 E90) garage space is tight so they are stored in my wheel wells! Great looking design! They are from a small company that once was, Forged 1.

Boot and shift knob. These will likely be a temporary solution as I plan to fabricate a gated shifter.

New-to-me oil pan arrived (eBay special) gave it a good cleaning and here is with the others.

I finished cleaning the engine bay, engine wiring harness, and the complete underbody which was either covered in oil from the blown motor of simply dirty from the 105,000 miles of service. EVERYTHING is nice and clean, just the way I like it.

Which brings me to the hurdle I will have to clear for mounting my transmission. My transmission tunnel has a large bulge and unique mounting locations for the 6AT+TC this car previously had and it is radically different than what I need to make the RWD E6X transmission support bolt to the chassis.

This will require a creative solution. I am hoping I can make a hybrid trans support which will utilize my old TC support and those chassis mounts but also reach far enough forward to properly support the MT. The good thing is there isn't a whole lot of weight the support needs to hold, it is more rotational torque from the engine. I will cross this bridge once the engine is in and the trans is mounted but this will arguably be the most "CUSTOM" part of my build...

Ordered some Redline 75w-140 (GL-5 +FM) because it sounds like people have had success with it and for the LSD flush it cost only $48, not $200+ for the oem BMW fluid, yes it is $50+ per 500ml.

Easy flush

Although those large particles seem odd, the condition of the old oil seems pretty good, it looks like it had been flushed as least once during it's previous 70,000 mile life.

#353

Thread Starter

Members

Senior Members

Joined: Feb 2008

Posts: 899

Likes: 13

From: San Diego

My Ride: E61 with all the mods

Model Year: 2008

Engine: N54

HERE IS THE POST FROM 4/24

I ended up making a tool to remove the rear differential bushings, part Habor Freight wheel bearing tool, part Home Depot hardware, part 36mm socket I have for the axle nuts. The 36mm socket was a great fit for the front bushings.

Bushings out

Oem vs MFactory Solid (rubber)

Bushings in

M5 axles in

Look how close the outer CV joint is to the wheel carrier!

My test fitting and eye balling suggested fitment would be tight but I didn't think it would be THIS tight! Clearance is literally 1-2mm

If it fits it fits!

LSD, the traction drug

Test fitting pull rods with the modified LSD heatsink.

Looking good

Exhaust should clear no problem

Cleaned up more heat shield

...and my RD Sport sways

#354

Thread Starter

Members

Senior Members

Joined: Feb 2008

Posts: 899

Likes: 13

From: San Diego

My Ride: E61 with all the mods

Model Year: 2008

Engine: N54

It was great but I had trouble coding my DSC (laptop/software issues) and never got my DSC/ABS out of an error state.

Evan

#355

Thread Starter

Members

Senior Members

Joined: Feb 2008

Posts: 899

Likes: 13

From: San Diego

My Ride: E61 with all the mods

Model Year: 2008

Engine: N54

Most of the E9X guys just disconnect the front driveshaft and pull a fuse and deal with all the shortcomings of not legitimately configuring the car for the new orientation.

Yes, trans is bolted to the engine which helps support the weight. Engine mounts are directly under the engine so once the trans is bolted up that weight shifts back but it still isn't a huge load for the trans support to hold. My MT only weights 97lbs or something like that, like I said it is more torque and twist that static weight.

Evan

#356

Thread Starter

Members

Senior Members

Joined: Feb 2008

Posts: 899

Likes: 13

From: San Diego

My Ride: E61 with all the mods

Model Year: 2008

Engine: N54

While the motor was out I investigated swapping my non-M DSC pump for an E60 M5, nearly everything else on the car is M5 so it made sense. It looks like the M5 DSC has an additional input "accelerator" sensor and I didn't want to bother with integrating that but what I really wanted to do is get the ugly ABS/DSC pump, module, hardl lines, and wiring out of the engine bay

The non-M location behind the passenger headlight is a HUGE eyesore and the M5 location behind the driver wheel liner make a lot more sense is it is location directly below the master cylinder. removing unnecessary runs of lines and improve aesthetics? My kind of mod.

After some research it looks like all I would need is the M5 hydraulic lines, the brackets for the pump, and to extend my wiring harness. I will probably create a DIY of the full process for the E6X guys but here are some pics of the process thus far. I am trying to track down the remaining hydro lines I need as I don't feel like paying "new" prices. The brackets are on the way via $31 and eBay, and the wiring harness is complete after purchasing some wiring and spending an annoying amount of time soldering all the connections.

OEM location

So ugly

Draining fluid

Overdue

Front hard lines removed

Old mounts and ugly stuff

Grdinging

Much better

Oem wiring harness

Split

New conduit

Crazy eyes

Solder solder solder solder

1/2 done

Solder solder solder solder

New routing

Motor rebuild and assembled.

In she go

Up next is the 6MT and figuring out how I am going to solve the issue with the rear support.

The non-M location behind the passenger headlight is a HUGE eyesore and the M5 location behind the driver wheel liner make a lot more sense is it is location directly below the master cylinder. removing unnecessary runs of lines and improve aesthetics? My kind of mod.

After some research it looks like all I would need is the M5 hydraulic lines, the brackets for the pump, and to extend my wiring harness. I will probably create a DIY of the full process for the E6X guys but here are some pics of the process thus far. I am trying to track down the remaining hydro lines I need as I don't feel like paying "new" prices. The brackets are on the way via $31 and eBay, and the wiring harness is complete after purchasing some wiring and spending an annoying amount of time soldering all the connections.

OEM location

So ugly

Draining fluid

Overdue

Front hard lines removed

Old mounts and ugly stuff

Grdinging

Much better

Oem wiring harness

Split

New conduit

Crazy eyes

Solder solder solder solder

1/2 done

Solder solder solder solder

New routing

Motor rebuild and assembled.

In she go

Up next is the 6MT and figuring out how I am going to solve the issue with the rear support.

Last edited by ucsbwsr; 08-10-2016 at 06:50 AM.

#358

Thread Starter

Members

Senior Members

Joined: Feb 2008

Posts: 899

Likes: 13

From: San Diego

My Ride: E61 with all the mods

Model Year: 2008

Engine: N54

#360

Thread Starter

Members

Senior Members

Joined: Feb 2008

Posts: 899

Likes: 13

From: San Diego

My Ride: E61 with all the mods

Model Year: 2008

Engine: N54

Engine is in, connected, oiled up, and coolant bled. Once my ********* get back from receiving their ceramic coating I can install them with my O2s and give the engine a crank.  Long time coming, just under 5 months.

Long time coming, just under 5 months.

Below are some pictorial updates. They may not work in certain browsers or on your phone, I am sorry, Google flipped Picasa in favor for a "better" image storage system that doesn't display on all platforms, if anyone has info on how to resolve this, I am all ears. Thanks Google.

Enjoy,

Evan

Not all the Tredwear decals made it through the incident when my engine blew.

Found this in my rear tire. I might just leave it and roast the rear tires so I can upgrade from 275 to 285 now that I don't have to worry about F-R rolling diameters and keeping the AWD system happy. I could use some more meat out back. A 285 on the 19x11 rear should match the stretch of the 245 on the 9.5 up front. Symmetry is beauty.

Stay organized

"DIY"

Serpentine belt installed

TB still had some carnage in it

After

Charge pipe and BOV cleaned up

My wagon had an additional heat exchanger for both ATF and coolant. I took it apart to investigate the internals. Ports with green gaskets are for ATF the other (and another port located on the backside of the aluminum part) were for coolant.

The bottom coolant port had a spring tensioned valve but it doesn't appear to move and consequently have a thermostat function, not sure what the deal is.

To delete the ATF connections I cut off the hardlines.

Assembled some hardware to block off the ATF ports

ATF function deleted but coolant still flows through the additional (and very small) heat exchanger, cooling is always welcomed.

Old ATF cooling lines

Decided it was a good time to paint my intercooler so it hides behind my bumper; keep it subtle, keep it classy

The rear bracket on my power steering pump is AWD specific and I now have a RWD oil pan so I needed to "make it work."

I bored out the hole in the bracket about 5-6mm to the left to compensate for the offset, I them reused an old M10 bolt from a rear axle and used a stainless steel nut as my 10mm spacer. MAcGyver mod.

My 10mm spacer

VTT turbo outlets and intercooler installed

Up pipe, charge pipe, and manifold installed

Oil filled, coolant filled and bled; vac tanks and solenoids installed.

Long time coming, just under 5 months.

Long time coming, just under 5 months.Below are some pictorial updates. They may not work in certain browsers or on your phone, I am sorry, Google flipped Picasa in favor for a "better" image storage system that doesn't display on all platforms, if anyone has info on how to resolve this, I am all ears. Thanks Google.

Enjoy,

Evan

Not all the Tredwear decals made it through the incident when my engine blew.

Found this in my rear tire. I might just leave it and roast the rear tires so I can upgrade from 275 to 285 now that I don't have to worry about F-R rolling diameters and keeping the AWD system happy. I could use some more meat out back. A 285 on the 19x11 rear should match the stretch of the 245 on the 9.5 up front. Symmetry is beauty.

Stay organized

"DIY"

Serpentine belt installed

TB still had some carnage in it

After

Charge pipe and BOV cleaned up

My wagon had an additional heat exchanger for both ATF and coolant. I took it apart to investigate the internals. Ports with green gaskets are for ATF the other (and another port located on the backside of the aluminum part) were for coolant.

The bottom coolant port had a spring tensioned valve but it doesn't appear to move and consequently have a thermostat function, not sure what the deal is.

To delete the ATF connections I cut off the hardlines.

Assembled some hardware to block off the ATF ports

ATF function deleted but coolant still flows through the additional (and very small) heat exchanger, cooling is always welcomed.

Old ATF cooling lines

Decided it was a good time to paint my intercooler so it hides behind my bumper; keep it subtle, keep it classy

The rear bracket on my power steering pump is AWD specific and I now have a RWD oil pan so I needed to "make it work."

I bored out the hole in the bracket about 5-6mm to the left to compensate for the offset, I them reused an old M10 bolt from a rear axle and used a stainless steel nut as my 10mm spacer. MAcGyver mod.

My 10mm spacer

VTT turbo outlets and intercooler installed

Up pipe, charge pipe, and manifold installed

Oil filled, coolant filled and bled; vac tanks and solenoids installed.

Last edited by ucsbwsr; 08-10-2016 at 06:59 AM.